LV124 / LV148 FULLY AUTOMATED TESTING SYSTEMS FOR 12V, 24V AND 48V

VW 80000, BMW GS95024-2-1, ISO 16750, GMW 3172, ISO 21780, MBN 10567, VW82148, VDA 320, MAN 3499 etc.

FULLY-AUTOMATED

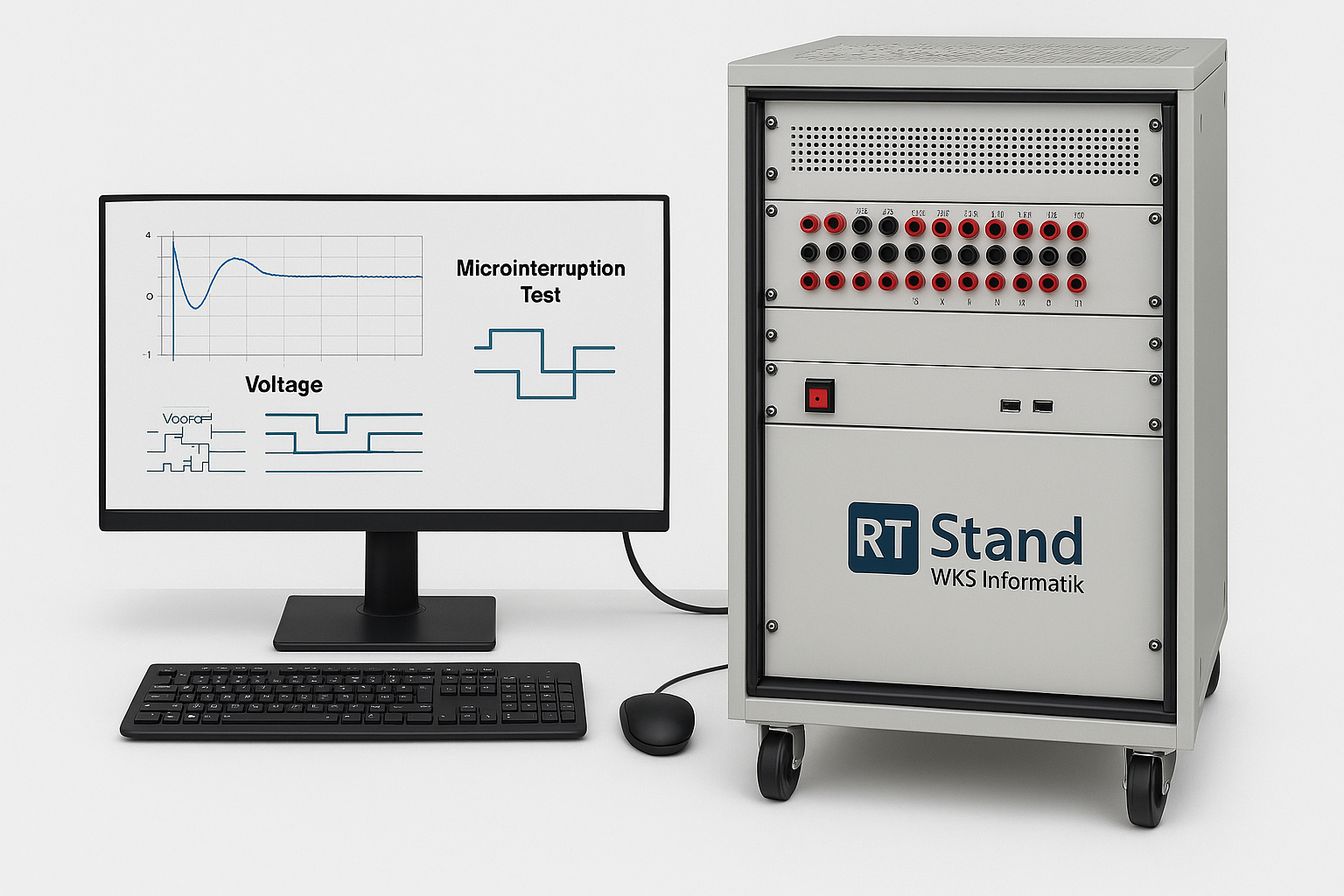

LV 124 / LV 148 TESTING SYSTEMS

The only fully automated systems worldwide in unique product quality!

Test all your ECUs for 12V, 24V and 48V power networks

Choose from various flexible layouts or define your own layout

Use it as a stand-alone or integrate it in HV testing setups

Buy or rent the system which suits your needs best!

TEST LABORATORY

FOR LV 124 / LV 148

Testing lab and engineering services with fully automated capabilities

Let us test your DUTs in our 100m2 lab

Let us test out new interface developments for you

Use our engineering and LV124 / LV148 expertise to improve your testing capabilities

Buy our services or partner with us in try-outs for new interfaces!

NEWEST DEVELOPMENTS FOR LV 124 / LV 148 AUTOMOTIVE TESTING!

FULLY-AUTOMATED 90A

LV 124 / LV 148 TESTING SYSTEMS

Same unique product quality, more power!

Our newest system supports up to 90A power consumption

Integrates seamlessly in our software framework!

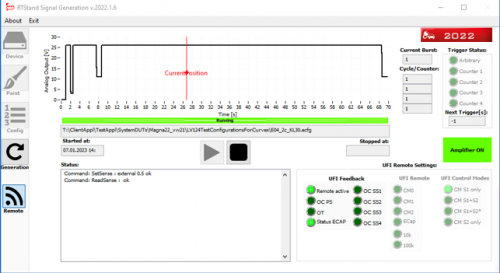

SIGNAL GENERATOR

UPGRADE

We have listened to our customers!

Software upgrade for feedback measurements during interruption and short-circuit tests

Software upgrade for support of several amplifier devices

Hardware upgrade for external control of additional UFI devices

UFI INTERRUPTION UNIT

FOR UP TO 10G ETHERNET

We keep up with new technologies!

Hardware developments for the newest series of UFI interruption devices

Support for up to 10G Ethernet and GMSL2

RENT SYSTEMS FOR LV 124 / LV 148 AUTOMOTIVE TESTING!

WE ARE TRUSTED BY

We have been using the RTStand LV124 / LV148 system from WKS Informatik for several years and are very satisfied with its high reliability and the fast, straightforward support. Regular maintenance and calibrations ensure that the system is always ready for use, and the personalized service significantly contributes to our satisfaction

SMR Automotive

The RTStand LV124 / LV148 system from WKS Informatik has not only increased our testing efficiency but also improved the workflow in our laboratory. Collaborating with WKS Informatik allowed us to implement custom adjustments, and we consistently benefit from prompt technical support. This efficiency and support have enabled us to effectively overcome the challenges of our dynamic development processes

Bühler Motor

The concept for automated testing of the LV124 prompted us to purchase a test system. The tests can now actually be performed and analyzed automatically. This saves time and resources. The support is also impeccable, and downtimes are minimized through a fast response time.

Leading automotive lighting supplier

We have reduced the overall testing time to a half compared to the previous manual testing and currently save 150.000 EUR for the LV124 testing of every several new software releases of our product

French automotive supplier

“One crucial advantage of your test system, besides timing and other benefits, is reproducibility! With a fully automated test run, there is no room for slight variations in the test runs anymore.”

Top 5 automotive supplier worldwide

This innovative modular concept, which gives us the opportunity to monitor a high number of pins in parallel, with a high resolution of up to 10us, as required in the LV124, allows us to make a deeper analysis of our products and especially find sporadic errors earlier in the development phase.

Continental™ AG

“..really appreciate the cooperation with you and your company!”

Bavarian car manufacturer

RTSTAND LV124 / LV148 – WHY IT MATTERS

FULLY AUTOMATED TESTING

Replaces manual procedures with 100% reproducible and repeatable test runs — essential for safety-critical ECUs.

FASTER TIME-TO-MARKET

Cuts testing time by up to 75% and enables continuous validation across development cycles.

BUILT FOR NORM COMPLIANCE

Covers all disturbance classes, communication checks, and environmental conditions.

FUTURE-PROOF INTERFACES

Supports Automotive Ethernet 1000base-T1, GMSL, and more.

PROVEN GLOBALLY

Trusted by top OEMs and Tier 1s in Europe, Asia, and North America.

RTSTAND LV124 / LV148 – KEY BENEFITS

UNIQUE CAPABILITIES

-

Cuts testing time by up to 75%

-

100% reproducibility

-

Customizable system layouts with 100+ pins

-

Fully automated control of climatic chambers

-

Continuous norm updates and system maintenance

COMPREHENSIVE LINE MONITORING

-

All power, current and communication lines monitored in parallel

-

Full signal coverage: CAN, LIN, Automotive Ethernet (1000Base-T1), GMSL, etc.

TEST TYPES COVERAGE

Including:

-

Short interruptions, short-circuits, backfeeds, offsets

-

Overcurrent, inrush current, sleep current

-

Randomized cranking etc.

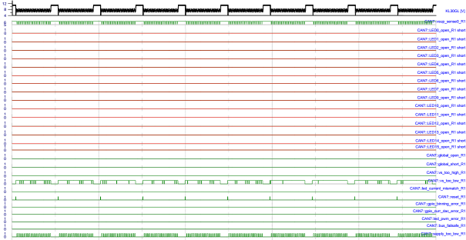

POWERFUL REPORTING

-

Fully automated report generation

-

Synchronized display of power, current, and communication data

-

Seamless integration with CANoe / CANape

RTSTAND LV124 / LV148 vs. COMPETITION / SETUPS

RTSTAND

LV124 / LV148

LV124 / LV148

SUPPORT

-

Fully integrated, out-of-the-box

-

Optimized for quick and compliant execution

-

Fully automated control of climatic chambers

-

Continuous norm updates and system maintenance

TEST TYPE

SUPPORT

-

Arbitrary waveforms, short interruptions, short-circuits, backfeeds, offsets

-

Overcurrent, inrush current, sleep current

-

Randomized cranking etc.

-

Ready-to-use, editable

ECU

MONITORING

-

All power, current and communication lines monitored in parallel

-

Full signal coverage: CAN, LIN, Automotive Ethernet (1000Base-T1), GMSL, etc.

REPORTING AND

ECU OPERATING MODE

-

Fully automated report generation

-

Synchronized display of power, current, and communication data

-

Seamless integration with CANoe / CANape

75% faster testing times

100% reproducibility

COMPETITION / MANUAL SETUPS / CUSTOM BENCHES

-

Manual setups, half-automation

-

Needs customization

-

Needs additional device integration

-

Only arbitrary waveforms

-

For all other test types, additional devices and integration is required

-

Only pulse output, NO actual testing!

-

NO native support for ECU I/Os and communication lines

-

NO automated report generation over all I/Os

-

NO Synchronized display of power, current, and communication data

-

NO integration with CANoe / CANape

High effort, highly custom, time consuming

NO reproducibility

RTSTAND LV124 / LV148 – WORKFLOW

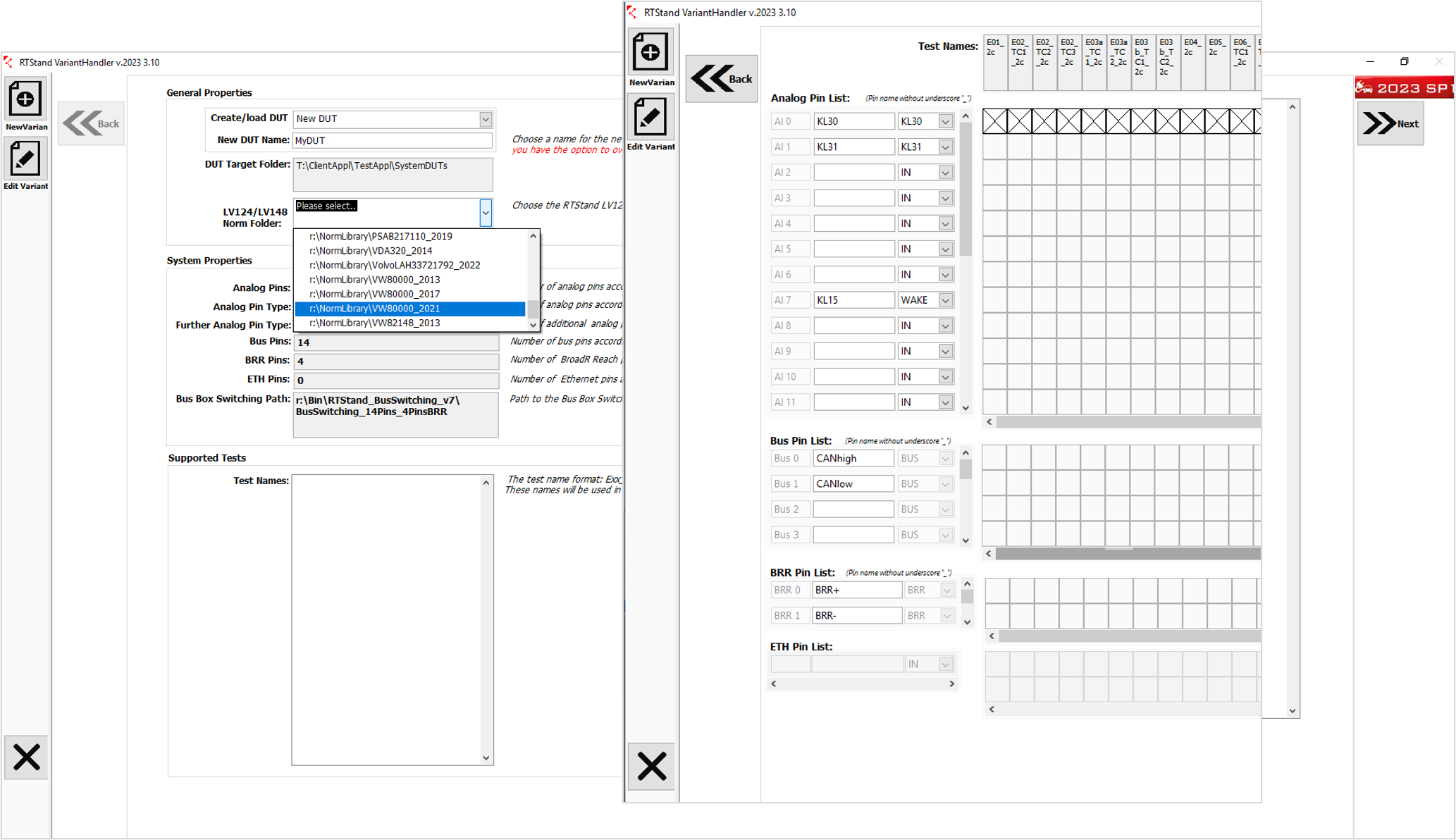

DEFINE DUT TO BE TESTED

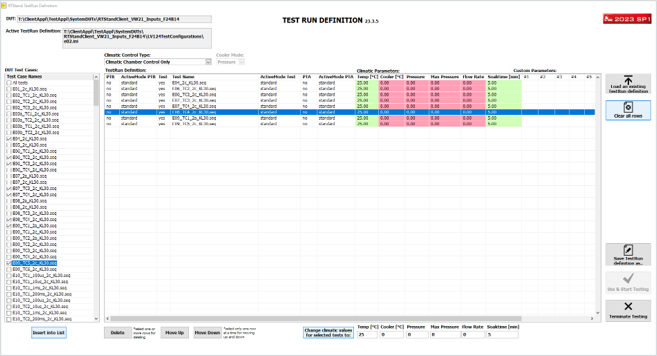

CHOOSE TEST ORDER AND RUN TESTS

FOLLOW LIVE TESTS

ANALYZE RESULTS

LV124 / LV148 – LIVE TEST RUN

RUN A FULLY-AUTOMATED TEST RUN

LV124 / LV148 – WHAT AI THINKS

LV124 and LV148 are critical automotive testing standards that define requirements for electrical, electronic, and mechatronic components used in vehicles with 12V, 24V, and 48V architectures. These standards ensure the robustness, reliability, and safety of automotive components under various electrical conditions. Below is a detailed overview:

## **LV124 and LV148 Overview**

– **Purpose**: Both standards specify tests for automotive components to ensure their proper functioning under different voltage conditions, including voltage fluctuations, overvoltage scenarios, and fault currents[1][2].

– **Scope**: They cover a wide range of components such as lighting systems, battery management systems, radars, Lidars, infotainment devices, pumps, cooling/heating systems, and intelligent computers[1][3].

– **Origins**: Developed by major automotive manufacturers like Audi, BMW, Volkswagen, Porsche, and Mercedes-Benz. These tests are integrated into OEM specifications such as VW 80000 and BMW GS 95024-3-1[1].

[…]

## **Advantages of Automated Systems**

Testing systems like RTStand LV124/LV148 offer several benefits:

– **High Precision**: Measurements comply with ISO 17025 standards with accuracy within 2%, often below 1%[1].

– **Automation**: Reduces human error and ensures repeatability while accelerating testing processes by up to 75%[1][5].

– **Cost Efficiency**: Minimizes manual efforts and lowers maintenance costs[1].

– **Scalability**: Supports various component types and test scenarios through flexible configurations[1].

## **Applications**

These standards are widely used in the automotive industry for validating components’ performance during development cycles. They help manufacturers ensure compliance with stringent quality requirements while reducing time-to-market for new products[1][3][5].

[…]

See the full Perplexity answer here: https://www.perplexity.ai/search/what-can-you-tell-me-about-lv1-KBKRaGCsQ0OmcWxepHuSuw?0=d&utm_source=copy_output

LV124 defines environmental and electrical test procedures for E/E components in vehicles. It’s designed to ensure components work reliably under real-world conditions (e.g., voltage drops, temperature changes, vibrations).

Key Test Areas:

-

Electrical Tests:

-

Overvoltage, undervoltage

-

Voltage drop (microinterruption tests)

-

Cranking voltage simulations

-

Slow ramping of voltage

-

Ground offset and supply modulation

-

-

Environmental Tests

-

Functional Tests

Use Case:

Mostly for 12V systems in passenger vehicles.

LV148 builds on LV124 and adds specific requirements for 48V electrical systems. It addresses the challenges of higher voltages (e.g., arcing, safety, energy storage) and hybrid components.

Key Features:

-

Specific electrical profiles for 48V systems

-

Testing for components like DC/DC converters, starter-generators, and lithium-ion battery packs

-

High voltage transients and safety evaluations

-

Compatibility with ISO 21780 (the international 48V standard, which LV148 partially inspired)

Tools Commonly Used for LV124/LV148 Testing:

-

RTStand (by WKS Informatik): Real-time test systems tailored for LV124/148

-

dSPACE, Vector, and National Instruments test setups

-

Programmable power supplies and load emulators (e.g., from Keysight or AVL)

-

RTStand LV124 / LV148: Ideal for labs needing fast, compliant testing for LV124 and LV148 with minimal setup.

-

Vector VT: Powerful for flexible testing, but requires extra effort to meet LV standards.

-

dSPACE: Scalable, suited for complex HIL environments but not tailored for LV124/LV148 out of the box.

-

NI Custom: Great for custom setups, but needs heavy engineering for compliance testing.

RTStand is a test automation software framework, often used in conjunction with hardware (like National Instruments PXI systems), specifically designed for validating automotive electronic control units (ECUs).

Here’s how RTStand, LV 124, and LV 148 are highly relevant to each other:

- LV 124 / LV 148 Define the Requirements: These standards detail the specific electrical tests (voltage variations, transients, interruptions, etc.) that an automotive component must pass. They define the waveforms, timings, voltage levels, and pass/fail criteria. They tell you WHAT needs to be tested.

- RTStand Provides the Execution Platform:RTStand is a tool used to implement and automate the tests defined by LV 124 and LV 148. It allows engineers to:

-

- Control Test Hardware: Interface with and control power supplies, electronic loads, signal generators, oscilloscopes, switching matrices, and other instruments needed to generate the required electrical stress conditions.

-

- Automate Test Sequences: Program the complex sequences of voltage changes, signal injections, and measurements prescribed by the standards. This ensures tests are repeatable and accurately follow the standard’s procedures.

-

- Monitor the DUT: Integrate with communication buses (CAN, LIN, Ethernet) and measurement hardware to monitor the Device Under Test’s (DUT) behavior and functional status during the electrical stress tests.

-

- Analyze Results & Report: Automatically acquire data, compare it against the pass/fail criteria from LV 124/148, and generate comprehensive test reports documenting compliance.

-

- Pre-built Libraries: Companies offering RTStand solutions (like WKS Informatik), often based on NI hardware/software like TestStand and LabVIEW) typically provide pre-configured test sequences or libraries specifically designed for executing LV 124 and LV 148 tests, significantly speeding up test system development.

In essence:

- You need to test your automotive component according to the rules set by LV 124 (for 12V systems) or LV 148 (for 48V systems).

- RTStand is a software framework (often part of a larger hardware/software test system) that provides the tools and automation capabilities to execute those specific LV 124 / LV 148 tests efficiently, reliably, and repeatably.

So, RTStand is highly relevant as it’s a practical tool used in the industry to perform the validation required by the LV 124 and LV 148 standards. It bridges the gap between the written standard and the physical execution of the tests on an ECU.

LV124 / LV148 – OUR NEWEST INNOVATIVE COMPONENTS FOR TESTING

Tube Analyzer F96flex NEW!

Measurement unit for up to 96 voltage or current channels (+/-10V)

UFI 100xBase-T1 NEW!

Interruption unit for Automotive Ethernet 100 and 1000base-t1 and GMSL lines

Tube Analyzer I12 NEW!

Measurement unit for up to 12 current channels (+/-5A)