What is LV124?

LV124 is a testing standard developed by a consortium of German automotive manufacturers — including Audi, BMW, Daimler, Porsche, and Volkswagen — to evaluate the electrical and environmental reliability of automotive electronic components. The goal of LV124 is to ensure the reliability and robustness of 12V and 24V automotive electronic components under real-world electrical and environmental stress conditions. LV124 covers a wide range of electrical and environmental tests, including:

-

Voltage variations (over-voltage, under-voltage, voltage dips)

-

Temperature and humidity cycling

-

Mechanical stress (vibration and shock)

-

Electromagnetic compatibility (EMC)

-

Power supply disturbances and transients

LV124 is widely used across the automotive industry worldwide, for components in traditional vehicles, as well as hybrid and electric vehicles.

Common Equivalent Names and Related Standards:

-

VW 80000 – Volkswagen’s internal test specification based on LV124

-

BMW GS 95024-2-1 – BMW’s adaptation of LV124

-

Daimler MBN 10567 – Mercedes-Benz adaptation of LV124

-

ISO 16750 – Often referenced for international comparison, though less detailed than LV124

-

etc.

What LV124 Covers:

-

Electrical tests: voltage dips, surges, short circuits, load dumps

-

Environmental tests: temperature cycling, humidity, corrosion

-

Mechanical tests: vibration, shock

-

Endurance testing over time

-

EMC considerations

What is LV148?

LV148 is the natural evolution of LV124, tailored for the demands of 48V electrical systems, which are becoming the new standard for mild hybrid and electric vehicle architectures. These systems require different testing protocols due to higher voltage levels and energy storage components. As the automotive industry shifts toward electrification, 48V systems offer a more efficient way to power high-demand components such as electric turbochargers, electric pumps, and mild hybrid systems.

LV148 includes many of the same test principles as LV124 but is adapted for the unique requirements of 48V systems. This includes:

-

Higher voltage level testing (nominal 48V with variations)

-

Enhanced transient behavior analysis

-

Testing energy storage and power distribution components

-

Safety and protection testing for high-voltage circuits

With LV148, manufacturers can ensure the safe integration of 48V technology into vehicles, supporting the industry’s push toward reduced emissions and improved energy efficiency.

Common Equivalent Names and Related Standards:

-

VW 82148 – Volkswagen’s internal 48V testing standard based on LV148

-

ISO 21780 – Focuses on power supply systems and safety for 48V architectures

-

etc.

What LV148 Adds:

-

Voltage range testing up to 60-70V

LV148 is critical for modern automotive systems using 48V architectures — enabling features like electric turbochargers, belt starter generators, active suspension systems, and more.

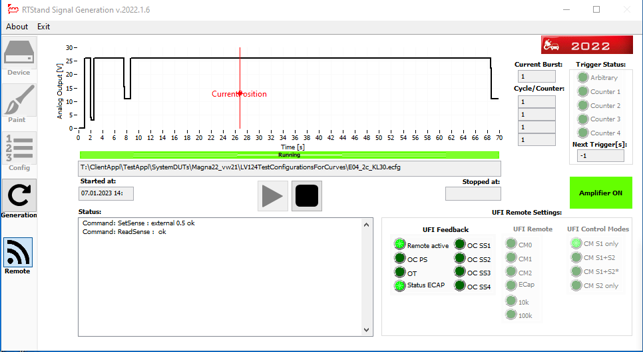

What is RTStand LV124 / LV148?

What LV124 / LV148 norms are supported?

The RTStand LV124 / LV148 family of systems are tailored for executing the demanding and often time-critical test cases defined in the LV124 (12V and 24V systems) and LV148 (48V systems) test specifications.

Key Features:

-

Out-of-the-box compliance with LV124 / LV148 tests

-

Fully automated test procedures for:

-

micro-interruptions

-

voltage dips and surges

-

short-circuits, feedback, offsets and overcurrents

-

slow ramp-up/down of voltage etc.

-

-

High-speed switching and timing accuracy in the microsecond range

-

Integrated fully automated reporting and logging

-

Ready for related standards

Why It Matters

Testing LV124 and LV148 manually is extremely complex, time-consuming, and prone to error due to the precise timing and voltage ramping requirements. RTStand provides a reliable, repeatable, and certifiable platform that accelerates development while reducing test errors and costs.

Fully Automated Testing

Replaces manual procedures with 100% repeatable test runs — essential for safety-critical ECUs.

Faster Time-to-Market

Cuts testing time by up to 75% and enables continuous validation across development cycles.

Built for LV124 / LV148 Compliance

Covers all disturbance classes, communication checks, and environmental conditions.

Future-Proof Interfaces

Supports Automotive Ethernet 1000base-T1, GMSL, and more.

Proven Globally

Trusted by top OEMs and Tier 1s in Europe, Asia, and North America.

Download an overview of the LV124 / LV148 norms here

For more information also check:

wks-informatik.de and our published documents

and our social media channels!

The norm library supported by RTStand LV124 / LV148 is subject to continuous development.

For the newest list, please contact WKS Informatik.

Currently more than 45 standards and specifications are supported out of the box:

AUDI LAH4N0419091 2021

AUDI LAH895941 2023

AUDI LAH89A947B 2024

BMW BTTests 2023

BMW GS95024-2-1 2010

BMW GS95024-2-1 2011

BMW GS95024-2-1 2021

BMW GS95024-2-1 2024

BMW NCAR 2023

FCA CS00054 2018

GMW 3172 2018

Hyundai HKMC ES95400-10 2015

ISO 16750-12V 2012

ISO 16750-12V 2023

ISO 16750-24V 2012

ISO 16750-24V 2023

ISO 21780 2020

JLR EMCCS 2013

KTM T201T202 2023

Lucid EEDRCS 2023

MAN 3499-2-12V 2017

MAN 3499-2-12V 2020

MAN 3499-2-24V 2017

MAN 3499-2-24V 2020

MBN 10567 2018

MBN 10567 2024

MBN LV124 2013

McLaren MSL03040004 2012

PSA B217110 2019

RenaultNissan RND SC00517 2022

Tesla TS0000425-05 2022

VDA 320 2014

Volvo LAH33721792 2022

VW 80000 2013

VW 80000 2017

VW 80000 2021

VW 80000 2022

VW 82148 2013

Zoox ESPS 2024

… and many more!