READY-TO-USE

LV 124 / LV 148 COMPONENTS

Whether you are looking for an innovative data logging and analysis device designed especially for LV 124 / LV148 needs, for a fault simulation unit for the interruption tests or for other specific components, we have the right product!

FULLY-AUTOMATED

LV 124 / LV 148 TESTING SYSTEMS

We build testing systems for your specific DUT. Built with innovative components for LV 124 / LV 148 testing and fully-automated, they help you save up to 50% of your testing time!

TEST LABORATORY

FOR LV 124 / LV 148

In our inhouse laboratory for LV 124 / LV 148, we can execute a wide range of LV 124 / LV 148 electrical, environmental and lifetime tests for you! We use our RTStand LV 124 to provide the best test results for you!

NOT SURE WHAT IS THE BEST SOLUTION FOR YOUR NEEDS?

REACH OUT TO US!

+ 49 751 768792 30

contact@wks-informatik.de

WHAT OUR CUSTOMERS SAY

“Because of RTStand we were able to detect a sporadic error we would not have found with the ols approach. This saved us a lot of money, as the failure has been detected in a very early stage of development of our gateway.”

Thomas Richter – Project Manager at Continental™ AG

“This innovative modular concept, which gives us the opportunity to monitor a high number of pins in parallel, with a high resolution of up to 10us, as required in the LV124, allows us to make a deeper analysis of our products and especially find sporadic errors earlier in the development phase.”

Ralf Zimmermann – Technical Project Lead at Continental™ AG

“We have reduced the overall testing time to a half compared to the previous manual testing and currently save 150.000 EUR for the LV124 testing of every several new software releases of our product.”

multinational automotive supplier

RTSTAND LV124 – PRO

FULLY-AUTOMATED TESTING SYSTEMS

SAVES >50% OF YOUR TESTING COSTS

Generic design for various kinds of DUTs

Modular layout, upgradable anytime!

Automated parameter tests

Fully automated PDF reporting

24/7 testing

FASTER ANALYSIS OF YOUR DUT

Flexible testrun definition with automated climatic chamber control

Continuous monitoring of all voltages and current in parallel

Support of various fieldbuses (CAN, LIN, Automotive Ethernet, GMSL etc.)

CANoe/CANape integration for restbus simulation

Extensive LV124 / LV148 norm library (VW 80000, BMW GS 95024-2-1 etc.)

GENERIC SYSTEM

TESTS ALL YOUR DUTs WITH ONE SYSTEM!

STANDARD LAYOUTS

UPGRADE YOUR SYSTEM ANYTIME!

PRODUCT QUALITY

GET YOUR SYSTEM IN 12 WEEKS!

INDEPTH ANALYSIS

AUTOMATED PDF REPORTS!

MANUAL SETUPS VS. RTSTAND LV124 PRO

MANUAL SETUPS

-

High testing and analysis times & costs

-

High human error potential

-

No support for 2/3 of the test cases

-

No generic design

-

No support of critical norm requirements: e.g. monitoring, operating mode, climatic chamber control, bus lines testing etc.

-

High manpower needed

-

Reduced or no maintenance and support capability

RTStand LV124 – PRO

-

Reduce testing and analysis times & costs

-

Reduce human error potential

-

Support for non-arbitrary test cases

-

Support for bus lines testing

-

Generic design for various kinds of ECUs

-

Support for critical norm requirements

-

Reduced needed manpower

-

Continuous maintenance and support

LET US SHOW YOU THE BENEFITS OF OUR SYSTEMS IN DETAIL!

REACH OUT TO US!

+ 49 751 768792 30

contact@wks-informatik.de

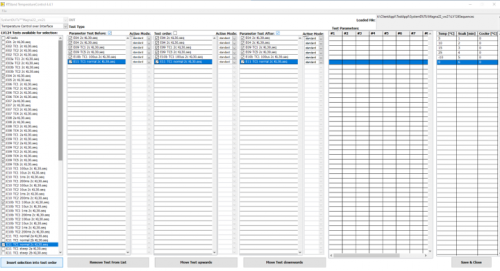

RTSTAND LV124 – WORKFLOW

DEFINE DUT TO BE TESTED

CHOOSE TEST ORDER AND RUN TESTS

FOLLOW LIVE TESTS

ANALYZE RESULTS

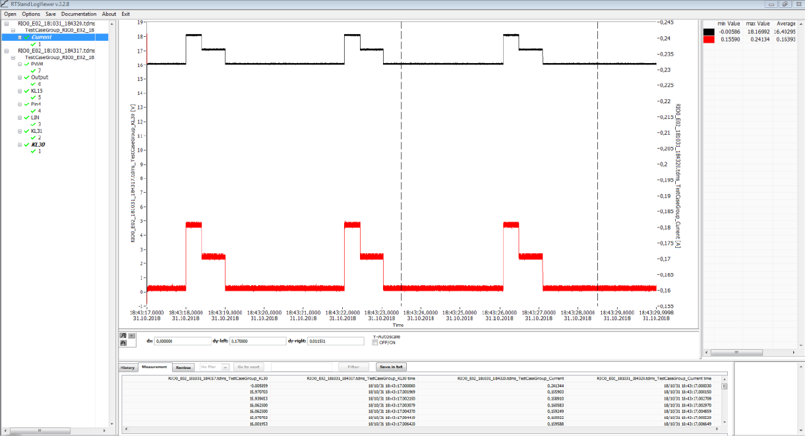

LV124 / LV148 – LIVE TEST RUN

DEFINE A DUT WITHIN MINUTES!

RUN A FULLY-AUTOMATED TEST RUN

ANALYZE RESULTS IN 25 SECONDS!

LV124 / LV148 – OUR COMPONENTS FOR TESTING

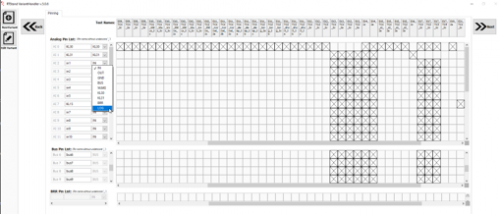

RTSTAND USER INTERFACE

Customizable User Interface for NI TestStand, with integration capabilities for various tools

RTSTAND

Customizable HiL test and simulation platform for development, validation and production purposes

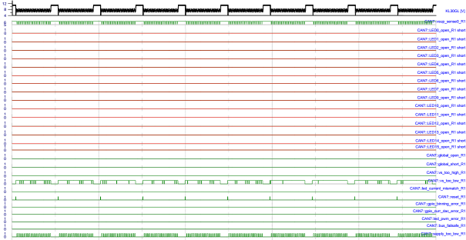

TUBE ANALYZER

Detection, analysis and logging of short sporadic errors for the automotive industry – LV 124 / LV 148

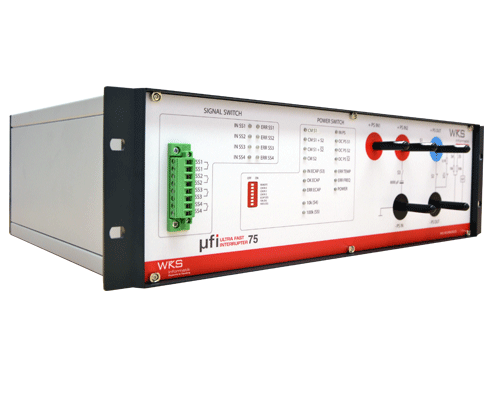

UFI

Ultra-fast Interrupter switch for LV 124 / LV 148, supporting also CAN, LIN, Automotive Ethernet etc.

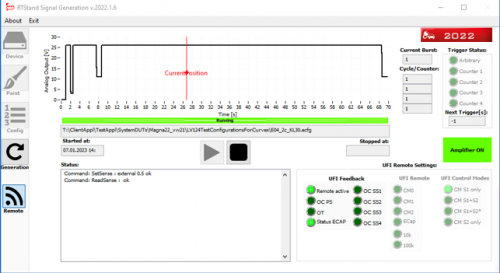

RTSTAND SIGNAL GENERATION

Signal generation device for LV 124 / LV 148 arbitrary pulses and interruptions

Tube Analyzer F96flex NEW!

Measurement unit for up to 96 voltage or current channels (+/-10V)

UFI 100xBase-T1 NEW!

Interruption unit for Automotive Ethernet 100base-T1, 1000base-t1 and GMSL / GMSL2 buses

Tube Analyzer I12 NEW!

Measurement unit for up to 12 current channels (+/-5A)